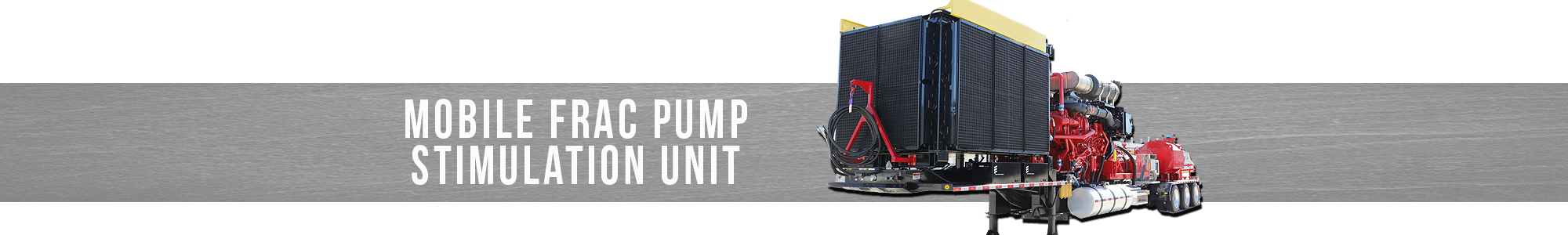

Dual Fuel Mobile Frac Pump Stimulation Unit

DP4000Q MTU

Mobile Frac Pump Stimulation Unit

Dual Fuel Mobile Frac Pump Specifications

Dragon Product’s MTU 4000 Dual Fuel Mobile Frac Unit is designed for continuous duty operations with a 2-rod compression system. This allows for removal and replacement of the fluid end without losing compression and alignment of the power end. The power end tie rods will last the life of the pump and only need to be removed at the power end overhaul. Fluid end tie rods may need periodic replacement (though this is far less than the legacy style stay rods).

The major components of our mobile frac units were chosen and designed to give you longer life before having to rebuild or refresh the power end. Routine maintenance schedule to extend the life of the power end is highly recommended.

Dual Fuel Mobile Frac Pump Engine

Our mobile frac pump is equipped with a robust MTU engine mounted on the trailer's deck. This comprehensive system includes air filters, exhaust systems, and oil and filters and more:

- Air Filters: MFG. Supplied

- Exhaust System: MFG. Supplied

- Alternator: 24VDC

- Starter: Single Hydraulic / Electric

- Oil And Filters: MFG. Supplied

- Batteries: (4) 12VDS, OPERATING IN SERIES, 24VDC SYSTEM

Transmission

A petroleum transmission with integral torque converter is mated to the deck engine of the Dual Fuel Mobile Frac Pump. Driveline includes a steel fabricated rotation guard that is connected to the pump.

- Model: Petroleum Transmission

- Flywheel: Mfg. Recommended

- Driveline: Mfg. Recommended

- Oil and Filter: Mfg. Recommended

- Transmission Oil: Mfg. Recommended

- Cooler: Transmission cooler included

- Miscellaneous: Mag pickup for driveline rotation, converted to BPM rate by

- system controls.

Cooling

A cube-style cooling package is installed on the front of the Dual Fuel Mobile Frac Pump.

- Coolers: lube, hydraulic, fuel

- Hydraulics: hydraulic motor, anti-cavitation valve, flushing valve

- Miscellaneous: surge tank, rad cap and sight glass, access panel, front and rear tri-mount, and support structure, steel signboards

Pump

Quintuplex Positive Displacement pump is mounted on the rear of the unit.

- Pump: Dragon 4000q Pump and Fluid End

- Fluid End: Dragon Stainless Steel Valve over Valve

- Rated Power: 4,000 BHP

- Stroke: 8”

- Gear Box Ratio: 6.963:1

- Maximum Pressure: dependent on fluid end size

- Lube Oil (Power End): as recommended by OEM

- Grease Lube (Fluid End): as recommended by OEM

- Miscellaneous: driveline flange as recommended by OEM

A drip tray is installed below the fluid end, which includes a 3/4” drain plug located on both ends for water to drain. There is also a 3” collar with a removable plug for clean-out underneath the drip pan.

Controls

- Engine Diagnostic Light

- Engine Protection Light Engine Diagnostic Port (On Engine)

- Main Power On/Off Switch

- Engine Ignition On/Off Switch

- Work Lights On/Off Switch

- Remote Control Cable Connection Port

- Over Pressure Instant Neutral System

- 15k Pressure Transducer

- Emergency Shutdown Button

Trailer Dimensions

- Capacity: 98,000 Lb.

- Overall Length: 50’

- Height: 13’6”

- Overall Width: 8’ 6

Mobile Frac Unit Options

- Discharge Bridle

- Cold Weather Package

- Multi-Pump System

- Data Tracs Data Acquisition System

- Hydraulic Starter Package