Electric Mobile Frac Unit

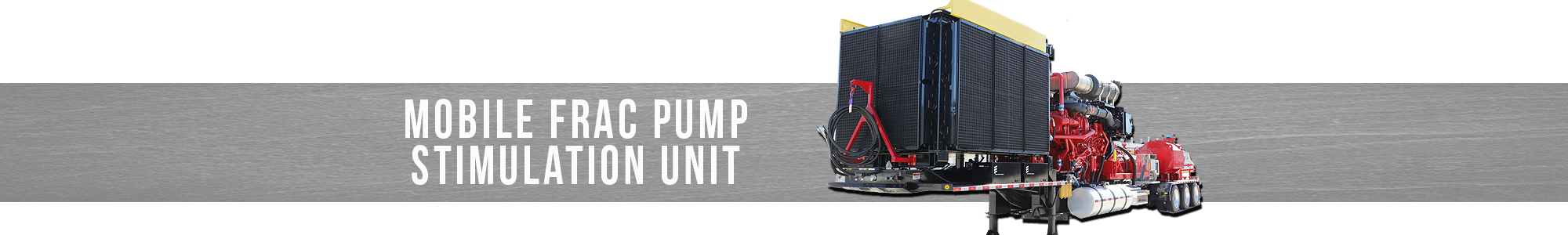

Mobile Frac Pump Stimulation Unit

SPECIFICATIONS

Dragon 4-Axle trailer with an 3300HP Electric Motor driving a Dragon DP4000Q Power End and Dragon XL Stainless Steel Fluid End

- Dragon 4-Axle Trailer with rear Drop

- Dragon DP4000Q Quintuplex

- Dragon Stainless Steel Fluid End

- 3300HP Electric Motor

- 2461 KW Power Cube

POWER CUBE

The Power Cube is an integrated system designed to supply power to oil and gas fracking process equipment. The Power Cube benefits are a space saving design able to be exposed to the weather and multiple environmental conditions. The Power Cube is composed of multiple components packaged in an ergonomic single enclosure that allow for power transformation and conversion. The entire cubicle will be mounted on a common skid. The electrical components will be interconnected reducing the need for external cabling of the components. There will be access through dust and waterproof cable glands into the cabinet for connecting to the driven equipment. The main driven equipment will be an electric motor as the prime mover of the process equipment. The cube will be a self-contained power center and encompass the main motor drive, auxiliary equipment loads, power transformer, and disconnect. The entire cube will be suitable for mobile transport and shock mounted.

POWER CUBE MAIN COMPONENTS SECTION

Transformer – A uniquely designed transformer that encompasses multiple taps and voltages specific to the application. The transformer will be aluminum wound with the following:

- 4800 kVA

- 13.8 kV Primary

- 720 VAC Secondary 1

- 480 VAC Secondary 2

Motor Control Center – The motor control center will be

IP66 rated and suitable for outdoor duty. The starters will

be incorporated into the power cube for the purposes

of providing a single source power cube application and

space savings. In addition to the motorized incoming

MCC breaker, a customer utility breaker and receptacle

has been added for low voltage customer testing.

- Lube Oiler Motor

- AC Motor Cooling Fans

- Spare

- 10 kVA – 480/208/120 VAC

Power Converter – The power cube will contain a

uniquely designed variable frequency drive power

converter to drive the main process motor. The drive

will be a liquid cooled design that will be enclosed in

an IP66 section of the power cube. The means to expel

heat from the cabinet will be through small radiator

style heat exchangers cooled by the below described

cooling section. The radiator heat exchanger is a means

of cooling the cabinets internal volume and air and is

unique to the design and eliminates the need for an

external air conditioner.

Cooling Section – The cooling section will be an electric

motor operated recirculating pump that pumps cooling

liquid through the cabinets radiators, drive system,

reactors, and rectifiers. The liquid is then cooled across a

fan cooled radiator and circulated.

AC MOTOR

• 3300 HP

• 690 VAC

• 40.3 Hz

• 2515 Amps

• 2200 RPM Max Speed

• .9 power factor

• 6 Pole

• 21,665 ft lbs nominal torque @ 800 RPM

• 32,496 ft lbs max torque

• Horizontal mount

• Single shaft extension

• Insulation Class H

• Connection: Wye

• VPI Form wound

• Ingress Protection IP44 (Open)

• Strip Heaters installed

• (6) 100 Platinum RTD’d installed on windings (2 per

phase)

• 100 ohm Platinum RTD per bearing

• (2) Cooling blower rated 25 hp, 3600 rpm, 460 volt,

3600 CFM, XP motor, 3 phase, 40c ambient, stainless

steel construction.

• Motor is designed and provided with a side mount

junction box

• XP Lockout device

• XP blower pressure

PUMP

- QUINTUPLEX POSITIVE DISPLACEMENT PUMP IS MOUNTED ON THE REAR OF THE UNIT.

- PUMP: DRAGON 4000Q PUMP AND FLUID END

- FLUID END: DRAGON STAINLESS STEEL VALVE OVER VALVE

- RATED POWER: 4,000 BHP

- STROKE: 8”

- GEAR BOX RATIO: 6.963:1

- MAXIMUM PRESSURE: DEPENDENT ON FLUID END SIZE

- LUBE OIL (POWER END): AS RECOMMENDED BY OEM

- GREASE LUBE (FLUID END): AS RECOMMENDED BY OEM

- MISCELLANEOUS: DRIVELINE FLANGE AS RECOMMENDED BY OEM.

- A DRIP TRAY IS INSTALLED BELOW THE FLUID END, WHICH INCLUDES A 3/4” DRAIN PLUG LOCATED ON BOTH ENDS FOR WATER TO DRAIN. THERE IS ALSO A 3” COLLAR WITH A REMOVABLE PLUG FOR CLEAN- OUT UNDERNEATH THE DRIP PAN.

TRAILER

- CAPACITY: 116,000 LB.

- OVERALL LENGTH: 51’

- HEIGHT: 14’

- OVERALL WIDTH: 8’ 6