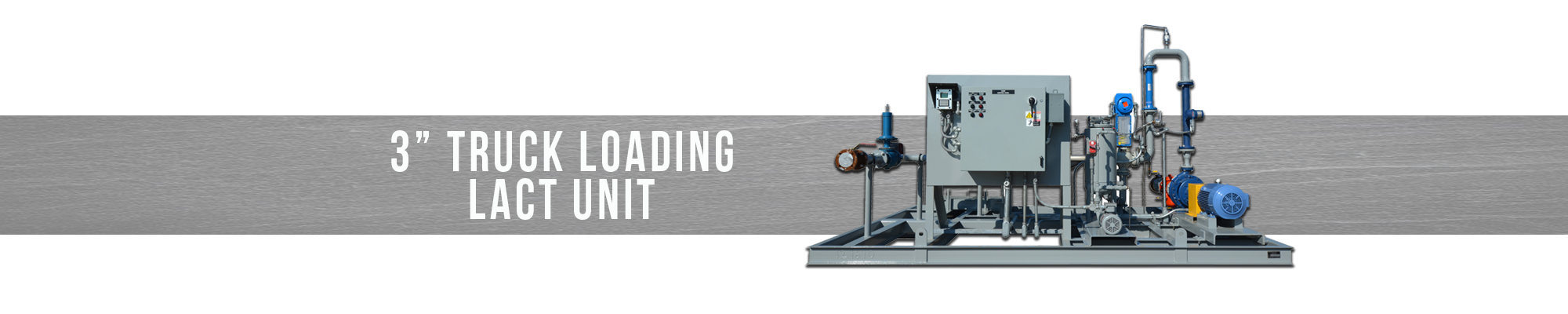

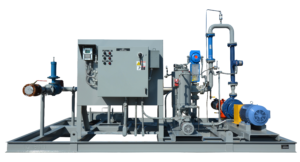

LACT Units

3” Truck Loading LACT Unit

SPECIFICATIONS

• Unit Type: Truck Loading LACT

• Product: Crude Oil

• Flow Rate: 310 GPM

• Discharge Pressure: 50 PSI (at pump outlet)

• Density: 40 API Gravity

• NPSHr: 5.91 ft.

• 4” KF ANSI 150# Full Port Floating Ball Valve.

• 4” Basket Strainer with stainless steel removable basket for maintenance purposes. Bottom drain piped to drain box.

• Griswold 3 x 2 -13 Centrifugal pump, 20 HP motor. 310 GPM, 50 PSI, 1800 RPM.

• 3” Invalco WCM 7300 BS&W Monitor to test water content in product. Connected to the divert valve and divert line.

• Armstrong 11-AV Air Eliminator, discharge piped to drain box.

• 3” Koflo 2-element static mixer, specifically designed for low pressure drop.

• Sampling Solenoid with volume regulator for periodic sampling based on current flow rate.

• Sample Skid with 15 gallon sample pot, centrifugal mixing motor, site glass, piping, static mixer, and return line to suction side of basket strainer.

• 3” ANSI 150# 3-way Divert Valve with ASCO Hydramotor actuator.

• Included in the divert line are a 3” wafer style check valve, 3” standard port isolation ball valve, and reduced orifice plate for back pressure.

• 2” ANSI 150# FMC Technologies Proline Promass Model 83F Coriolis Meter.

Dual pulse outputs for simultaneous direct connection to both flow computer and prover. Configurable screen and output parameters.

• Pressure Gauge, 4.5” dial face, 0-300 PSI.

• FMC Technologies platinum 4-wire RTD connected to flow computer for temperature compensation.

• Thermowell for 3” piping.

• (2) 3” ANSI 150# KF Floating Point Full Port Ball Valve for proving loop.

• 3” ANSI 150# KF Trunnion Mounted Full Port Double Block and Bleed Valve for closing flow through the sales line during proving operations.

• (2) 1/2” ball valves for drainage of prover piping.

• (2) 3” Cam Lock fittings on end of prover connections.

• 3” ANSI 150# diaphragm style back pressure valve with adjustable spring.

• 3” Balon wafer style check valve.

• 3” 150# KF Standard Port Floating Ball Valve for skid isolation.

• On-skid control panel containing motor starter, transformer, external ethernet connection and necessary wiring with indication lights for pump status, divert status and system errors.

• FMC Technologies microLoad.net Flow Computer for automated skid operations. Includes remote connectivity, volume flow data storage and temperature compensation algorithms.